Basic Theory and Microscopic Research of Copper Foil

查看更多

The performance of electrolytic copper foil is affected by its own crystal structure. Through the rational regulation of additives in the electrolysis process, the reaction potential of copper deposition can be changed, thus influencing the microstructure and morphology of the copper foil.

Through decades of technological accumulation, Defu Technology has focused on and made breakthroughs in key projects such as the physical property correlation of microscopic grain characteristics, the research on material stress and elastic modulus characteristics, and the theoretical model of copper foil roughness.

Ultra-fine roughening

查看更多

In response to the development trend of thinner and lighter PCB boards and the low transmission loss characteristics of high-frequency and high-speed circuits, polymer additives have been developed to achieve the purpose of customized design of copper nodules on the copper foil surface. This technology also takes into account low roughness and sufficient peel strength, making it the key to copper foil manufacturing technology.

Low - Ferromagnetic Barrier Layer

查看更多

In the metal barrier layer of copper foil for electronic circuits, there are factors that hinder signal transmission, and such effects will be further amplified in high-speed PCBs. In response to this phenomenon, a low-ferromagnetic metal barrier layer has been developed, which reduces the loss during signal transmission to a certain extent.

Silane coupling agent

查看更多

According to customer needs, we specifically developed the adaptation technology for silane coupling agents, which improved the chemical bonding performance between copper foil and various high - frequency and high - speed resin substrates.

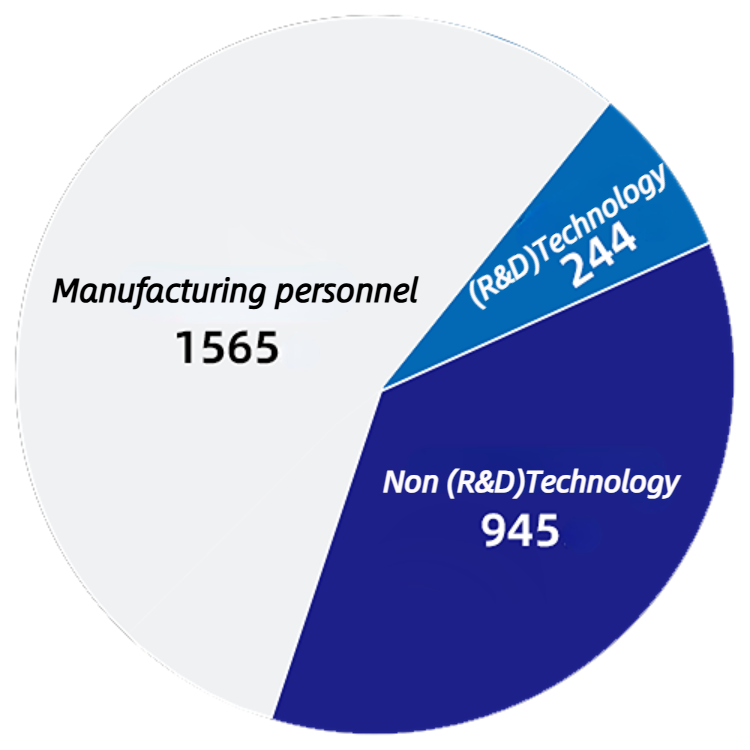

The company has 2869 employees.

115 with master's degree or higher

244 R & D staff

1565 in production

945 non - R & D technical personnel

Note: The above data was collected in May 2024.

a powerful R & D team

Since its establishment, Defu has been committed to independent innovation and core equipment localization. We see key tech and talents as the foundation, and have cultivated an industry-leading team. Comprising mainly middle-aged and young members from fields like mechanical design, materials physics, electrical engineering and automation, they have rich experience. Among them are doctors, masters and senior engineers, bringing cutting-edge tech and innovative solutions.

Defu's R & D team focuses on several fields like lithium battery copper foil equip., surface treatment & quality control tech, and new materials dev., taking on many national and provincial sci-tech projects. The team optimizes current tech and explores new ones and materials to boost industry progress

The company keeps investing in research and delving into it, building strong core competitiveness for Defu in lithium battery copper foil. This continuous input and innovation help Defu lead in battery material and high-performance copper foil production, driving its steady growth and long-term success in the industry.

Defu's R & D team focuses on several fields like lithium battery copper foil equip., surface treatment & quality control tech, and new materials dev., taking on many national and provincial sci-tech projects. The team optimizes current tech and explores new ones and materials to boost industry progress

The company keeps investing in research and delving into it, building strong core competitiveness for Defu in lithium battery copper foil. This continuous input and innovation help Defu lead in battery material and high-performance copper foil production, driving its steady growth and long-term success in the industry.

Establish four major laboratory platforms.

Kuafu Laboratory, Qomolangma Laboratory, Tiangong Laboratory, Analysis and Testing Center.

The laboratories cover about 10,000 m², with over 300 million yuan in investment and more than 100 sets of advanced equipment for experiments and tests.

The laboratories cover about 10,000 m², with over 300 million yuan in investment and more than 100 sets of advanced equipment for experiments and tests.

-

Kuafu LaboratoryKuafu Laboratory emerged to overtake Japan in high-end electronic circuit copper foil. As a disruptor, it aims to smash import monopolies, evolving from follower to leader, replacing imports with domestic products. It embodies craftsmen's patriotism and self-improvement, and restores pride to China's high-end copper foil manufacturing.

Kuafu LaboratoryKuafu Laboratory emerged to overtake Japan in high-end electronic circuit copper foil. As a disruptor, it aims to smash import monopolies, evolving from follower to leader, replacing imports with domestic products. It embodies craftsmen's patriotism and self-improvement, and restores pride to China's high-end copper foil manufacturing. -

Qomolangma LaboratoryBorn for challenges, innovation and breakthroughs, it has grown from scratch, refined from coarse to fine through repeated tempering, making the legend of China's lithium - battery copper foil come to life at Defu Technology

Qomolangma LaboratoryBorn for challenges, innovation and breakthroughs, it has grown from scratch, refined from coarse to fine through repeated tempering, making the legend of China's lithium - battery copper foil come to life at Defu Technology -

Tiangong LaboratoryDriven by unrestrained thinking and based on simulation, it conducts subversive innovation on existing technologies.

Tiangong LaboratoryDriven by unrestrained thinking and based on simulation, it conducts subversive innovation on existing technologies. -

Analysis and Testing CenterIt can independently test and analyze lithium battery copper foil performance and inspect and optimize other advanced copper foil materials. These support R & D of efficient lithium battery production processes and line optimization.

Analysis and Testing CenterIt can independently test and analyze lithium battery copper foil performance and inspect and optimize other advanced copper foil materials. These support R & D of efficient lithium battery production processes and line optimization.

Industry-leading R&D and analysis capabilities

-

EBSD (Electron Backscatter Diffraction)Backscatter Diffractometer

EBSD (Electron Backscatter Diffraction)Backscatter Diffractometer -

Inductively Coupled Plasma Optical Emission SpectrometerSpectrometer

Inductively Coupled Plasma Optical Emission SpectrometerSpectrometer -

Laser Confocal MicroscopeMicroscope

Laser Confocal MicroscopeMicroscope -

Argon Ion Polishing InstrumentPolishing Instrument

Argon Ion Polishing InstrumentPolishing Instrument -

Field Emission Scanning Electron MicroscopeElectron Microscope

Field Emission Scanning Electron MicroscopeElectron Microscope -

Scanning Electron MicroscopeMicroscope

Scanning Electron MicroscopeMicroscope -

CVS Detection SystemSystem

CVS Detection SystemSystem -

Vector Network AnalyzerAnalyzer

Vector Network AnalyzerAnalyzer -

Vector Network AnalyzerAnalyzer

Vector Network AnalyzerAnalyzer

University-enterprise Collaboration

The company has formed a “production, learning, research and application” mechanism. It has carried out industry-university-research cooperation projects with research institutes or universities such as College of Chemistry and Molecular Engineering of Peking University, South China University of Technology, Department of Chemistry of Renmin University of China, Suzhou University of Science and Technology, Xiamen University, Lanzhou University and Jiangsu University. It promotes scientific research cooperation between post-doctoral workstations and enterprises, and introduces a number of doctoral personnel to advance the industrialization of scientific and technological achievements.

Through industry-university-research cooperation and strong cooperation among leading enterprises in the industry, the company has organically combined laboratory research and production line technology development, and successfully achieved breakthroughs in key equipment and technologies for copper foils and other fields.

Through industry-university-research cooperation and strong cooperation among leading enterprises in the industry, the company has organically combined laboratory research and production line technology development, and successfully achieved breakthroughs in key equipment and technologies for copper foils and other fields.

Chinese Academy of Sciences

Peking University

Renmin University of China

Xiamen University

South China University of Technology

Suzhou University of Science and Technology

Lanzhou University

Patent Achievements

Relying on its strong R & D team, Defu Technology and subsidiaries have applied for 567 patents and got 343 authorized ones.

There're 60 core invention patents and over 100 utility model patents. Also, 5 computer software copyright certificates, all originally obtained.

There're 60 core invention patents and over 100 utility model patents. Also, 5 computer software copyright certificates, all originally obtained.

-

9P.

-

12P.

-

567P.

-

60P.

-

10P.

-

343P.

Note: The above data was counted/stated/collected on April 12, 2025

Some important honors

19 national and provincial technical honors

-

2021National High - tech Enterprise

-

2021National Enterprise Technology Center

-

2021The Third Batch of National “Little Giant” Enterprises

-

2021MIIT Intelligent Manufacturing Demonstration Factory

-

2021Provincial Enterprise Technology Center

-

2022Postdoctoral Research Station

-

2023National Green Factory

-

2024Jiangxi Provincial Key Laboratory