Product Center

Lithium copper foil

-

GT

-

Ordinary strength double-sided lithium battery copper foil

Double sided lithium battery copper foil is a copper foil produced by electrolysis, with both sides having a glossy finish. The Puqiang double-sided light lithium battery copper foil (GT) produced by Defu Technology has high ductility, uniform thickness, good conductivity and wettability, and stable product performance. As a negative current collector for lithium-ion batteries, it is widely used in energy storage batteries, automotive power batteries, and 3C digital batteries.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

High Ductility

Thickness Uniformity

Good Conductivity -

product information

Representative characteristic data

-

-

MT-40

-

Medium intensity double-sided lithium battery copper foil

The medium strength double-sided light lithium battery copper foil (MT-40) produced by Defu Technology has high tensile strength, high elongation, and stable product performance. As a negative current collector for lithium-ion batteries, it reduces copper foil wrinkles and breakage during battery cell manufacturing and subsequent use, and is widely used in energy storage batteries, automotive power batteries, and 3C digital batteries.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

High Tensile Strength

High Elongation Rate

Stable Product Performance -

product information

Representative characteristic data

-

-

HT-50

-

High strength double-sided lithium battery copper foil

The high-strength double-sided lithium battery copper foil (HT-50) produced by our company has high tensile strength, uniform thickness, and low roughness. It has strong resistance to external forces such as rolling and winding of the negative electrode plate of lithium batteries, reducing the occurrence of copper foil fracture and capacity reduction. It is suitable for high-capacity rechargeable batteries and widely used in industries such as large-scale energy storage, new energy vehicles, consumer electronics, and micro nano devices.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

High Tensile Strength

Thickness Uniformity

Low Roughness -

product information

Representative characteristic data

-

-

UHT-60

-

Ultra high strength 60 double-sided light lithium battery copper foil

As the proportion of high expansion coefficient silicon oxygen or silicon carbon negative electrodes increases, there are more stringent requirements for the tensile extension of the negative electrode current collector. The UHT-60 lithium battery copper foil produced by Defu Technology has a tensile strength of>60kgf/mm2 and also has an elongation of>4% (copper foil thickness of 6 μ m), which is of great benefit to the production and use of lithium batteries.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

High Tensile Strength

Excellent Thermal Stability

High Elongation Rate -

product information

Representative characteristic data

-

-

HM-50

-

Double sided lithium battery copper foil with high elastic modulus

The high elastic modulus double-sided photovoltaic lithium battery copper foil (HM-50) produced by Defu Technology has high modulus performance, strong flexibility, bending resistance, resistance to breakage, and high conductivity. As a negative current collector for lithium-ion batteries, it can effectively improve the structural stability of the battery, reduce heat generation, increase the energy conversion density of the battery, extend the service life of the battery, and improve safety. It is widely used in 3C digital batteries.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

High Elastic Modulus

Not Easily Broken

Higher Conductivity -

product information

Representative characteristic data

-

-

LM-50

-

Low elastic modulus double-sided lithium battery copper foil

The low elastic modulus double-sided photovoltaic lithium battery copper foil (LM-50) produced by Defu Technology has low roughness, low modulus performance, high tensile strength, and is easy to stretch and stretch. As a negative electrode current collector for lithium-ion batteries, it can avoid electrode breakage during the winding and compaction process, improve battery production efficiency, safety and service life, and is suitable for energy storage batteries and automotive power batteries.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

Low Modulus Performance

Low Roughness

Easy To Stretch And Stretch -

product information

Representative characteristic data

-

-

HE

-

High elongation double-sided lithium battery copper foil

The high elongation double-sided light lithium battery copper foil (HE) produced by Defu Technology has low roughness, extremely high ductility, and stable product performance. As a negative current collector for lithium-ion batteries, it can increase the compaction density, reduce the probability of electrode depression, wrinkling, and strip breakage in the battery cell process, improve production efficiency, reduce battery internal resistance, improve battery capacity, cycle life, and safety. It is suitable for long cycle and high rate lithium-ion batteries.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

Extremely High Elongation Rate

Low Roughness

Stable Product Performance -

product information

Representative characteristic data

-

-

PCF

-

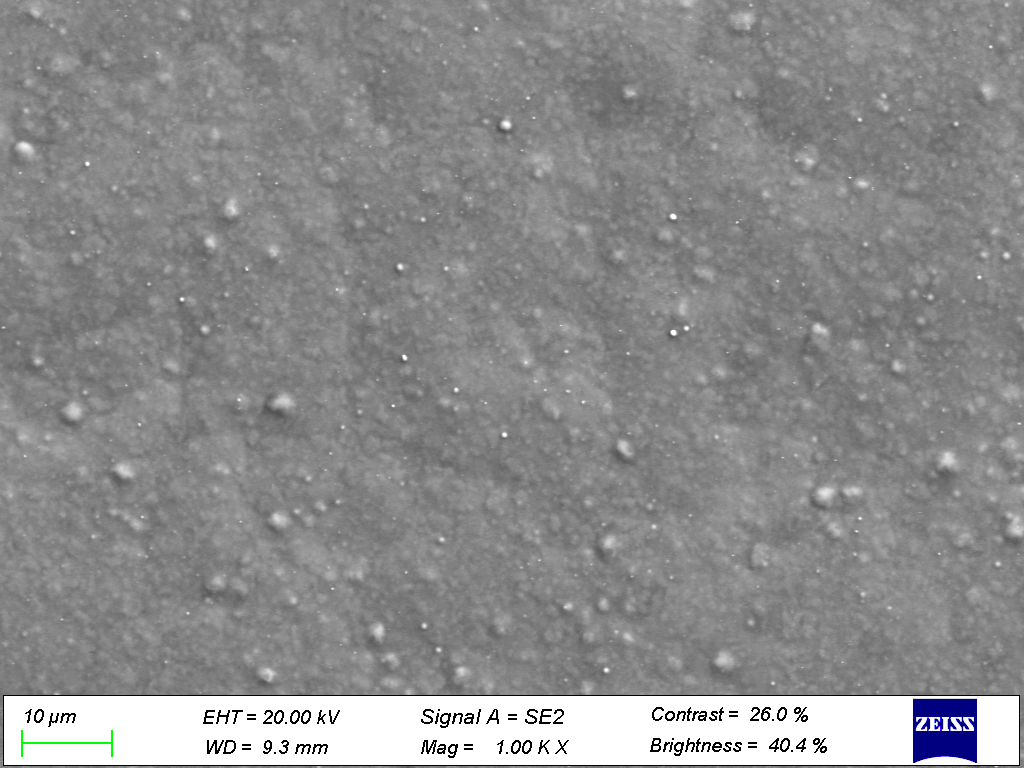

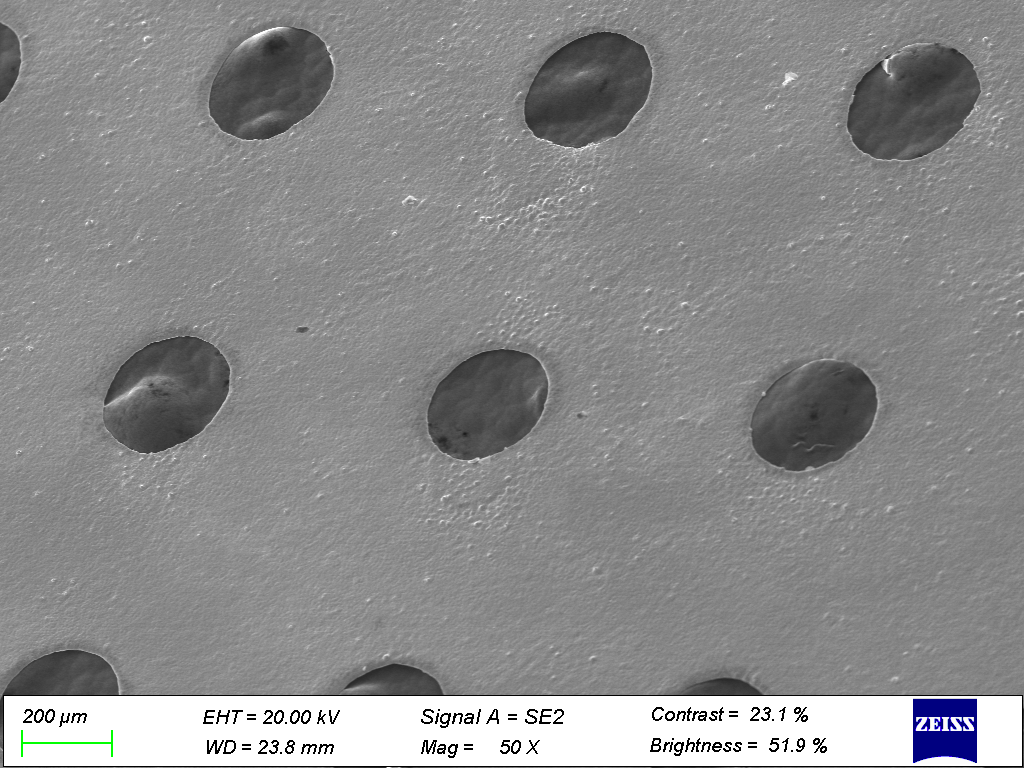

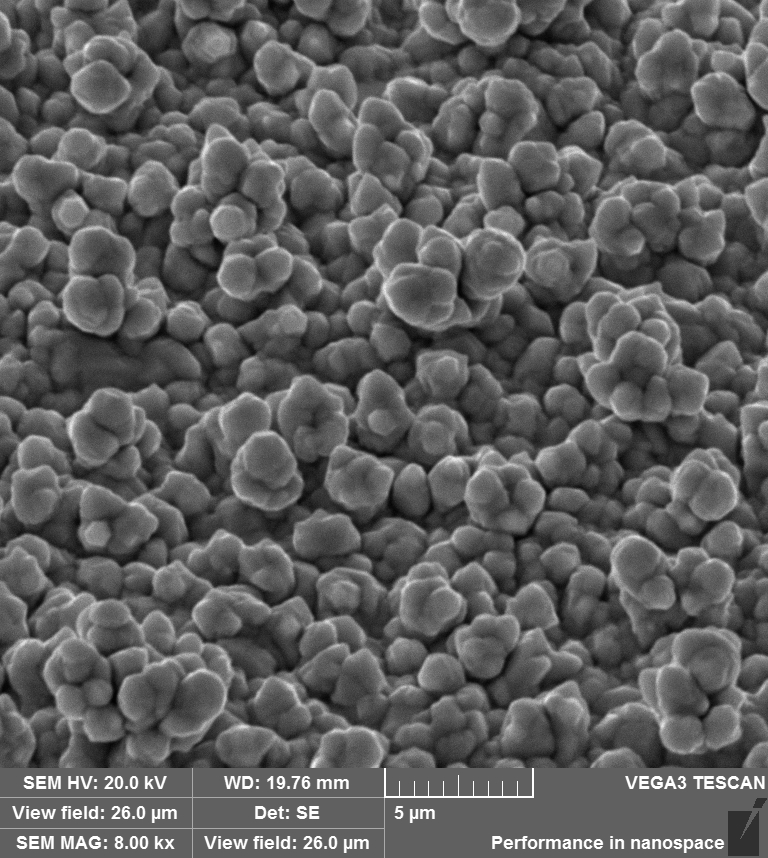

PCF porous copper foil

PCF copper foil is an important component of lithium-ion capacitors and solid-state lithium-ion batteries. For lithium-ion batteries, the advantage of PCF copper foil lies in its anchoring of metallic lithium and increasing the adhesion between metallic lithium and copper foil, reducing the interface impedance between the two, thereby improving the energy density of the battery. For solid-state lithium-ion batteries, PCF copper foil current collector carries the active material of the electrode, provides lithium-ion channels for pre lithiation of the electrode, improves the infiltration efficiency of the electrolyte, and can concentrate the current.

-

Downstream Applications

Energy Storage Battery

Automotive Power Battery

3C Digital Battery -

Typical Characteristics

Improve battery energy density

Improve the adhesion between lithium metal and copper foil

Improve electrolyte infiltration efficiency

Enhance battery safety -

product information

Representative characteristic data

-

-

ACF

-

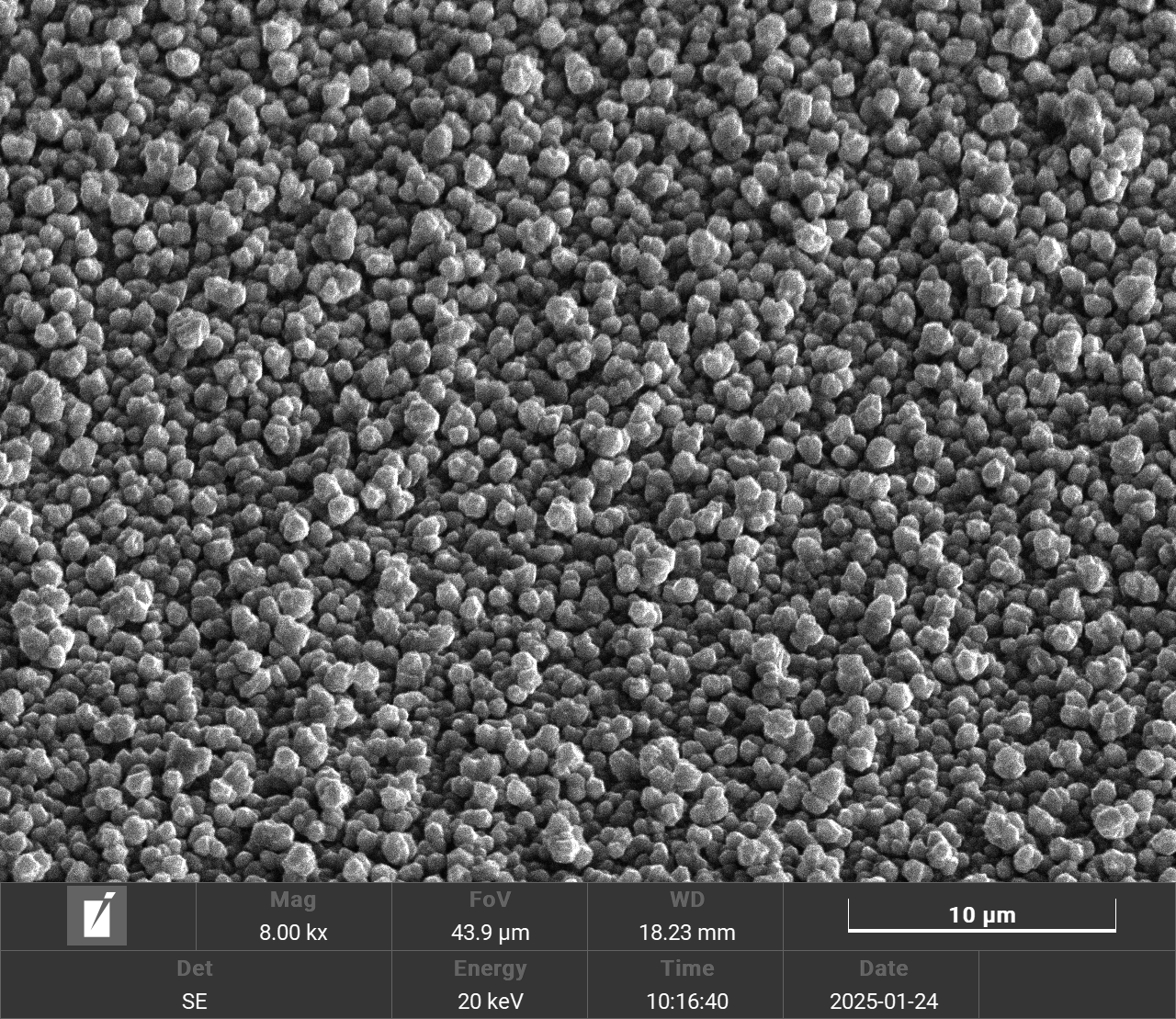

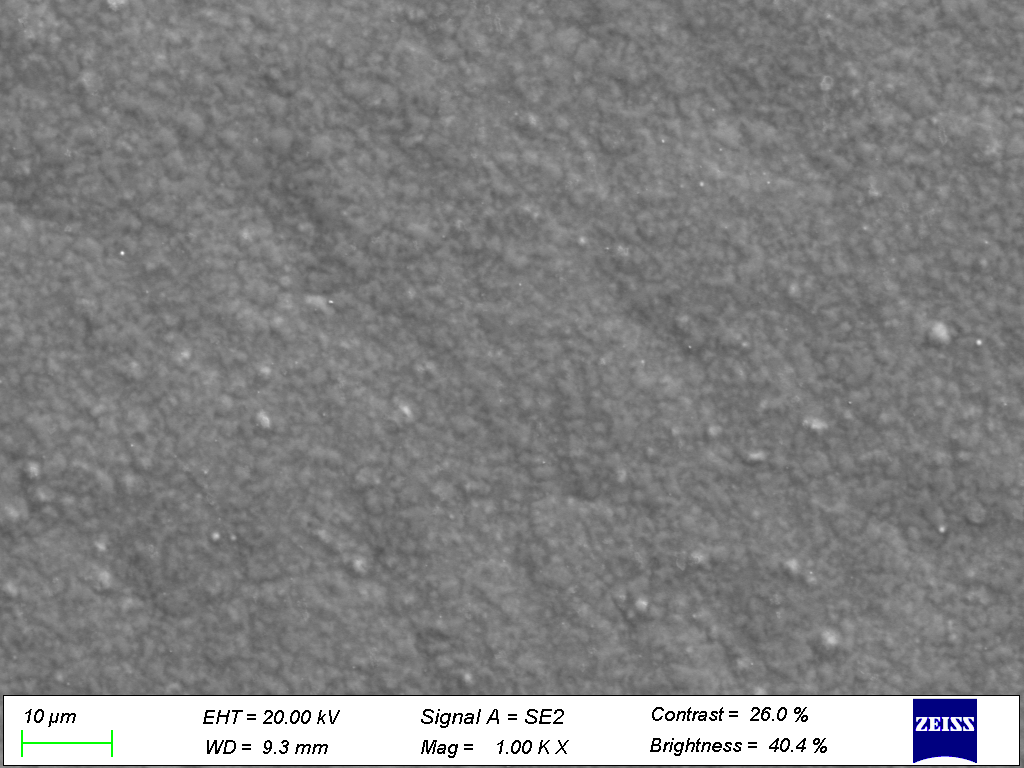

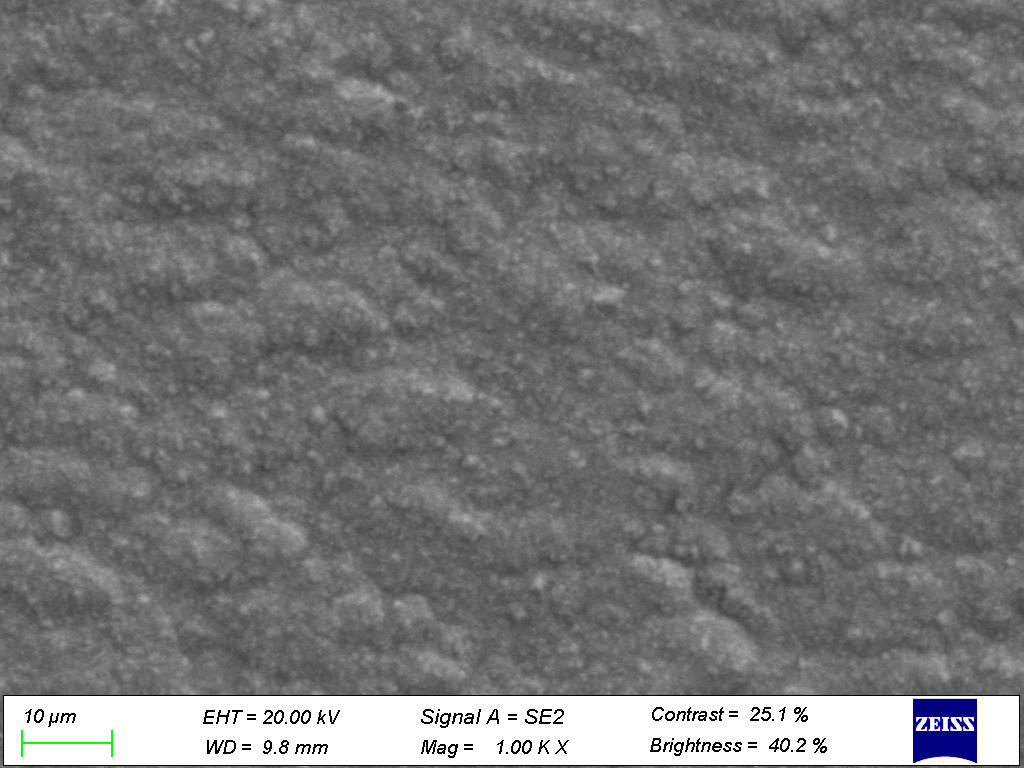

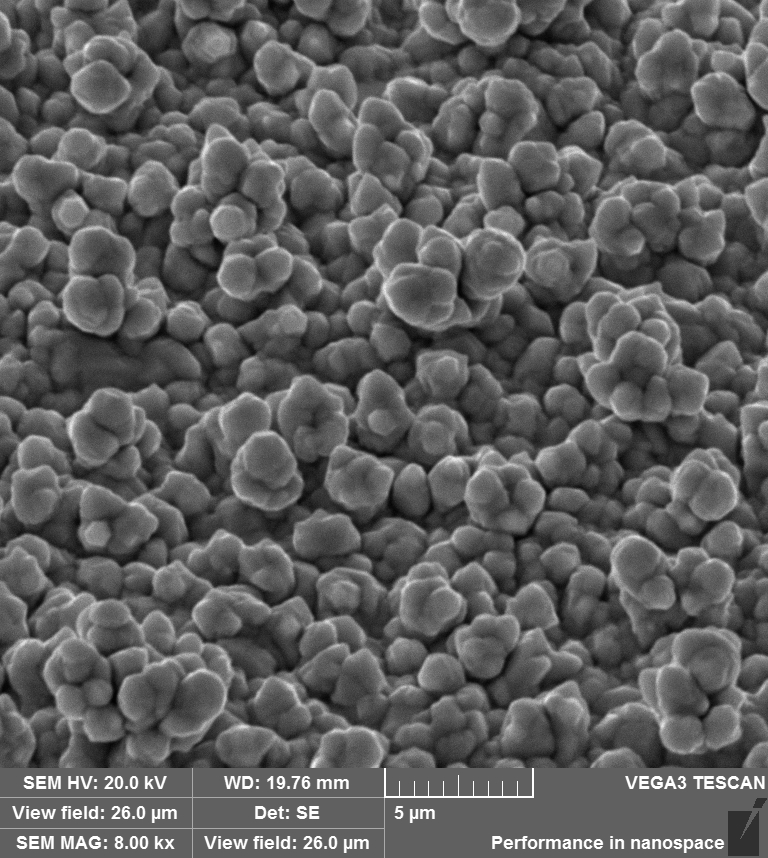

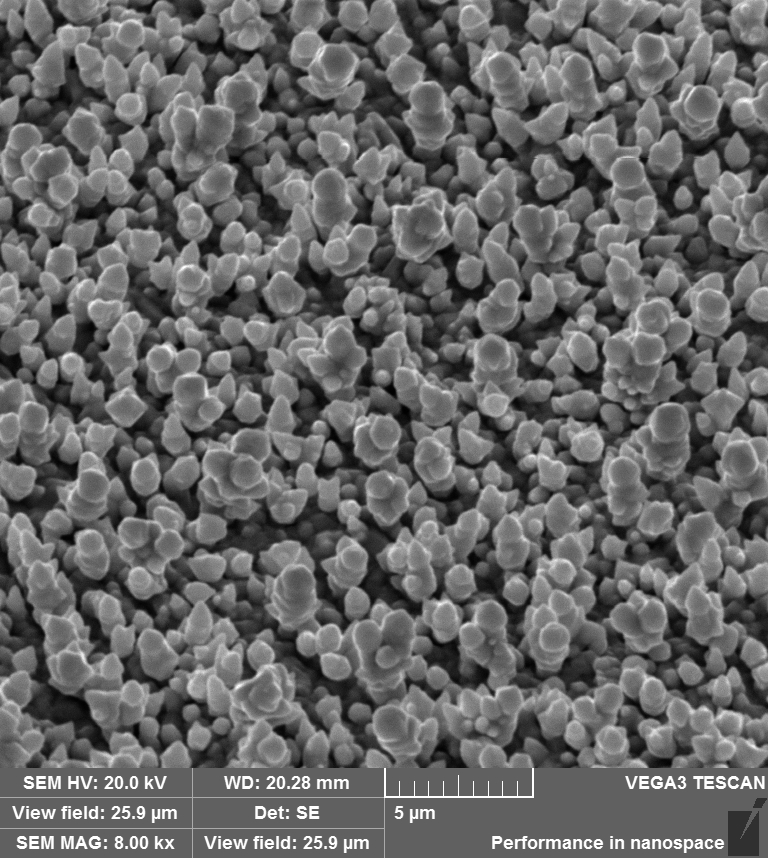

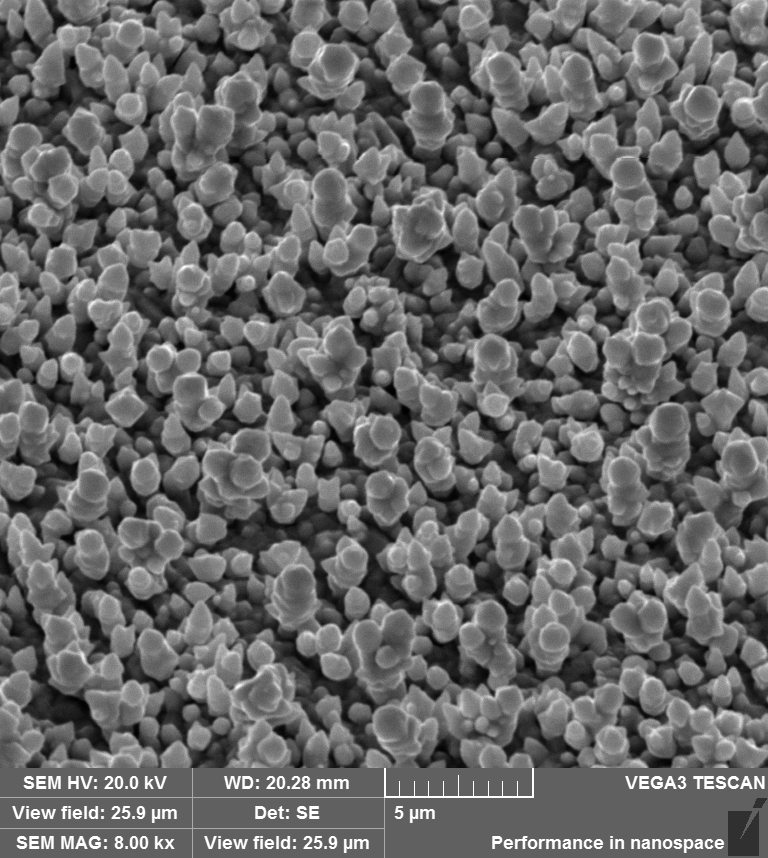

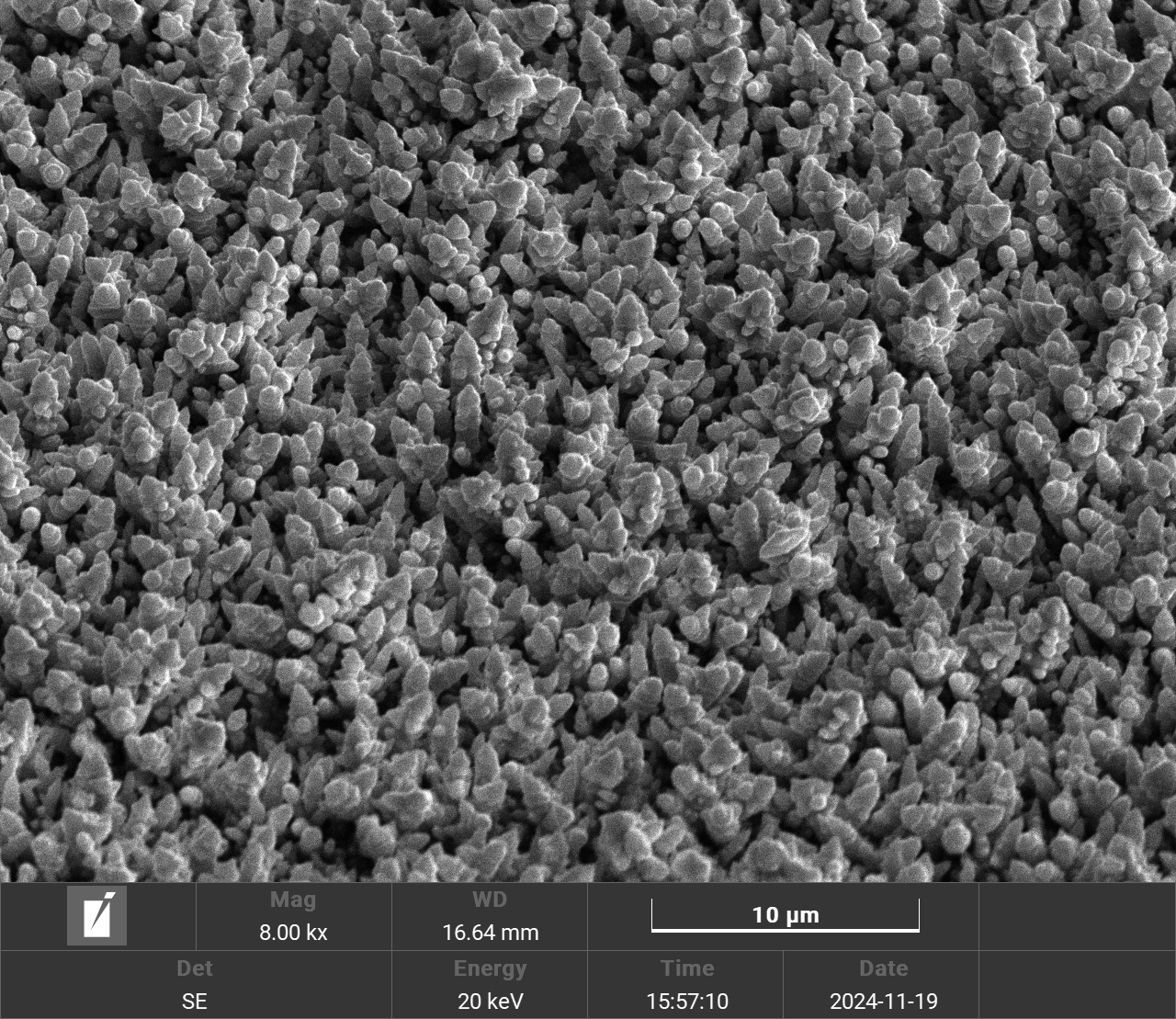

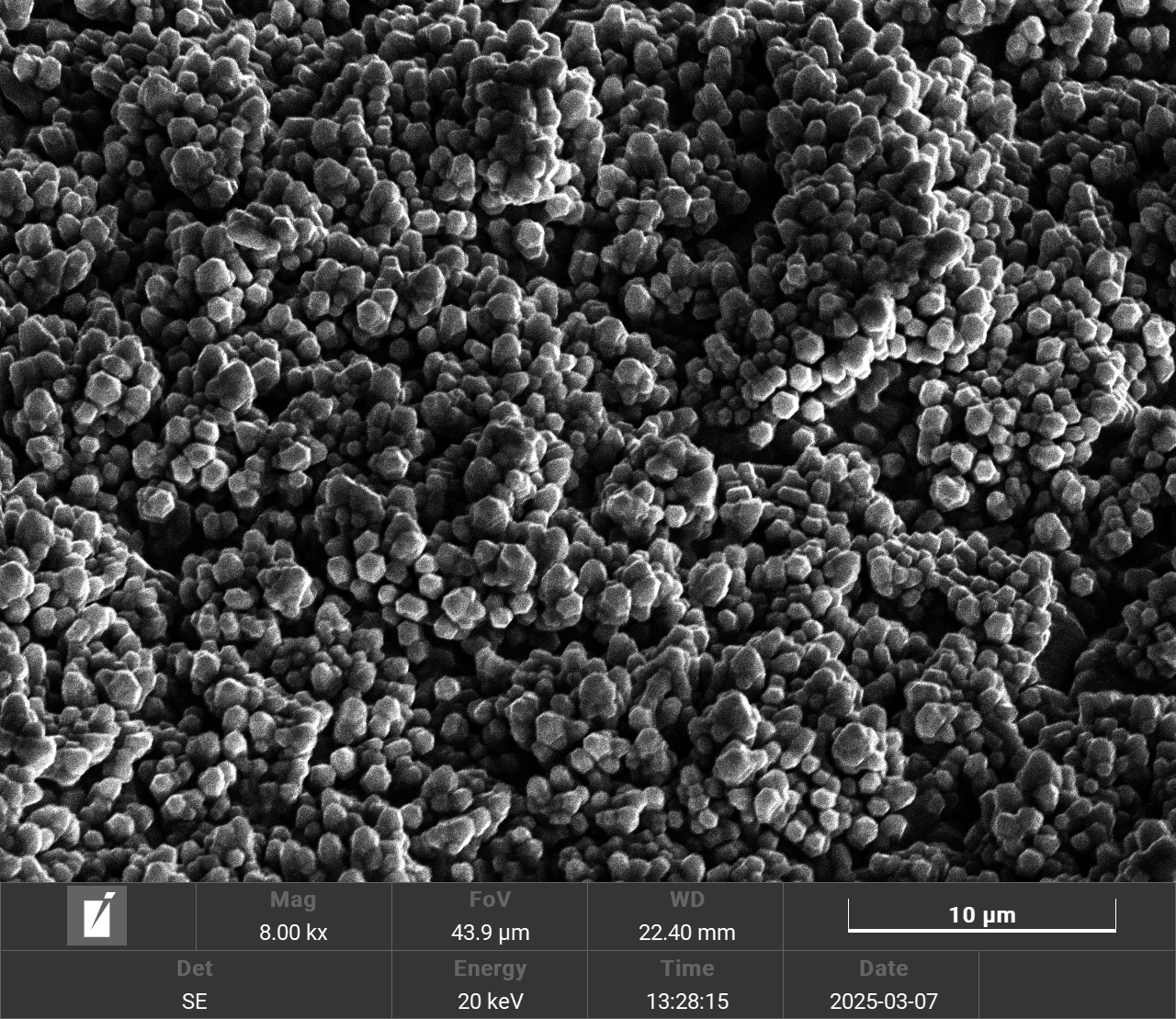

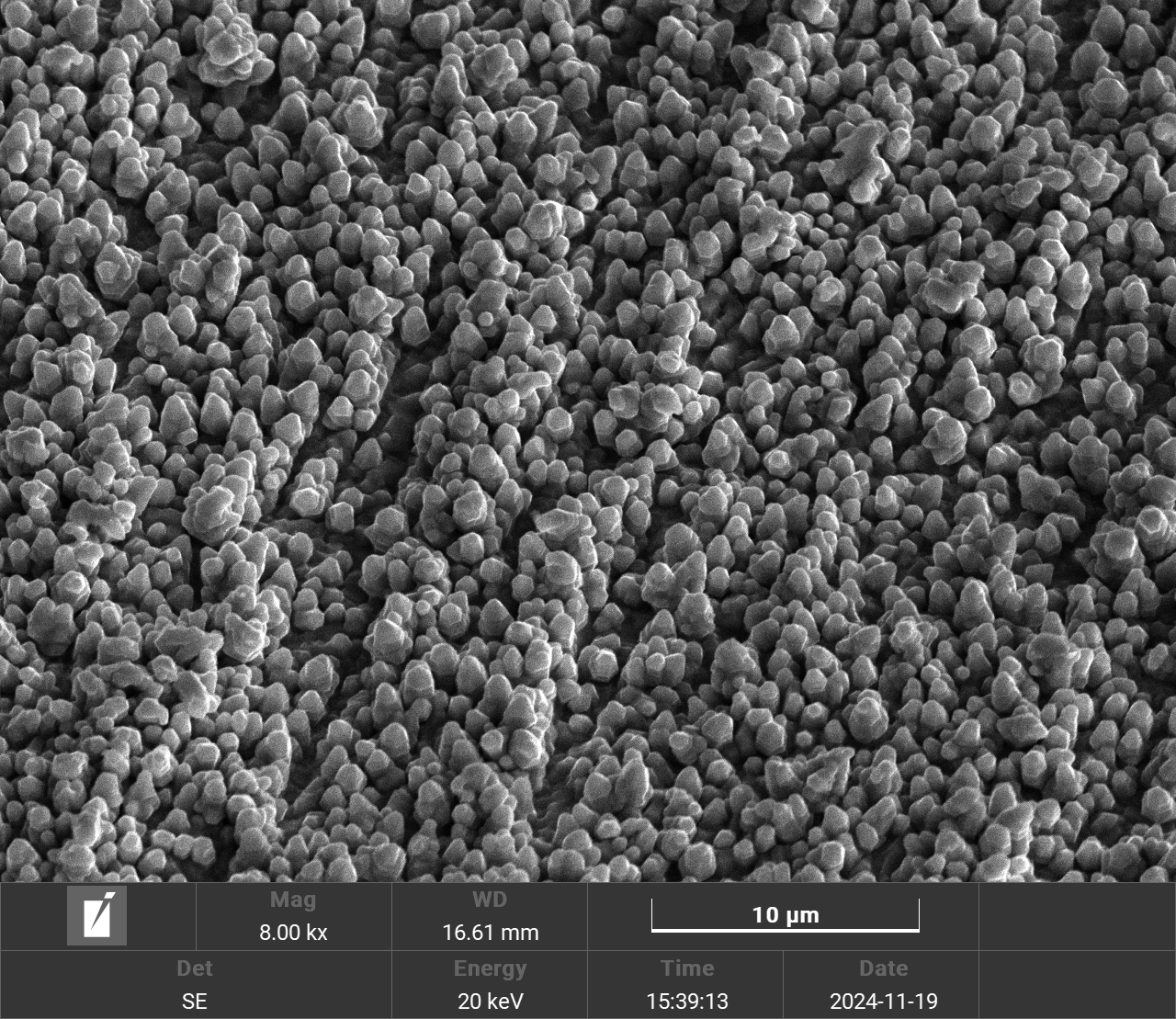

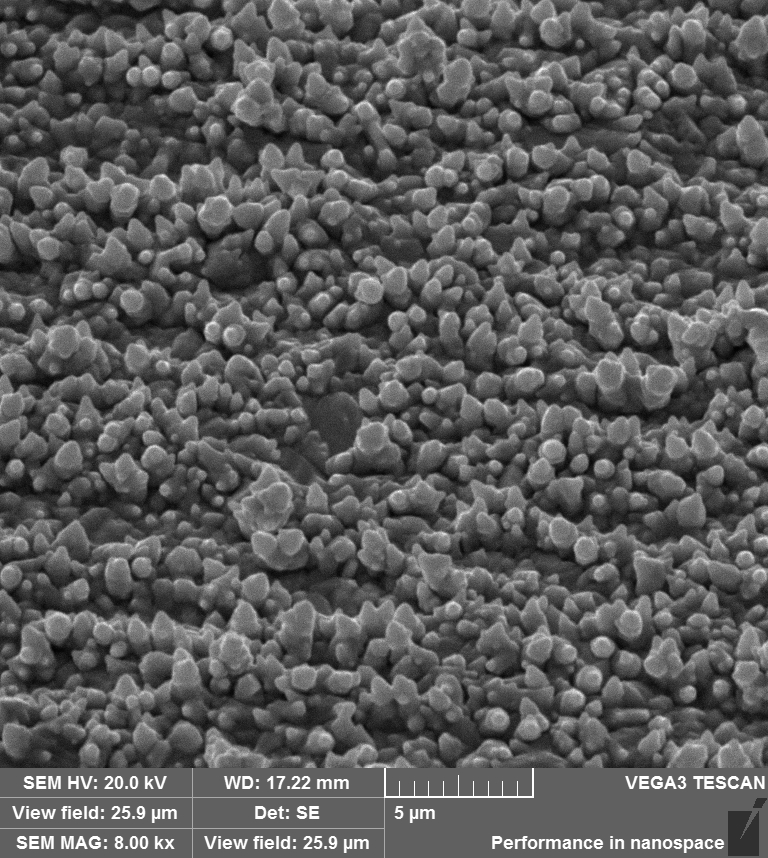

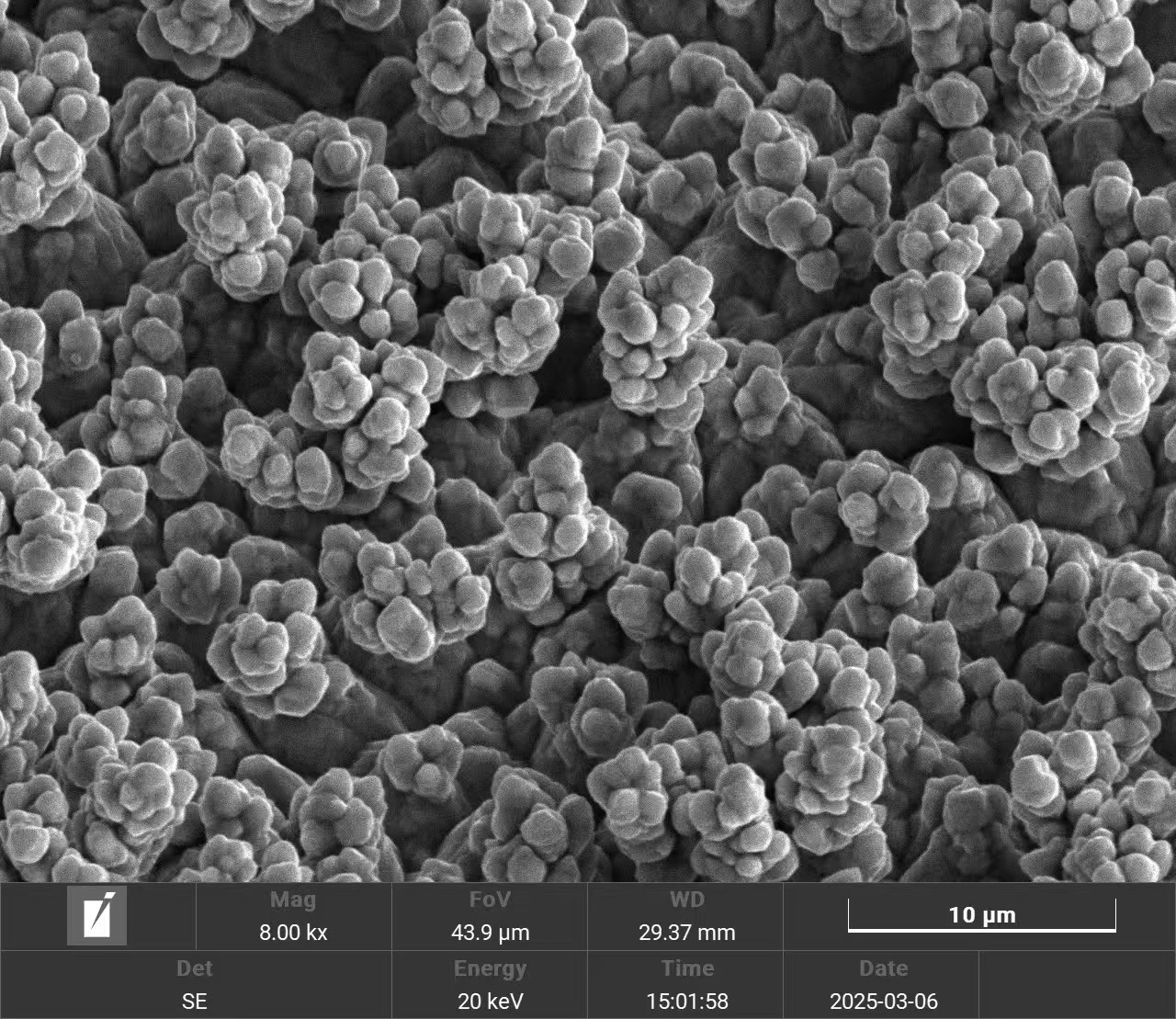

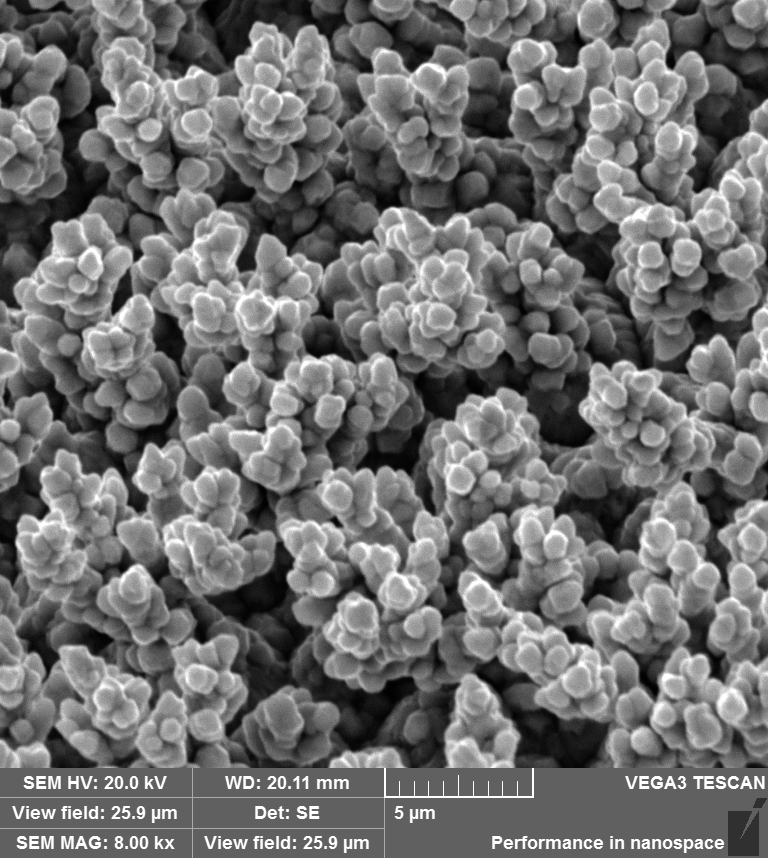

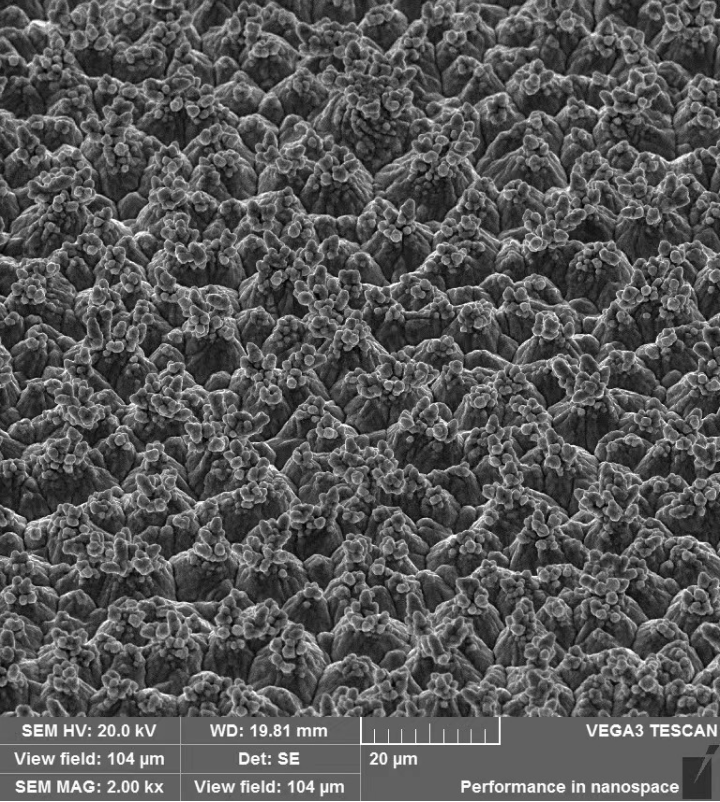

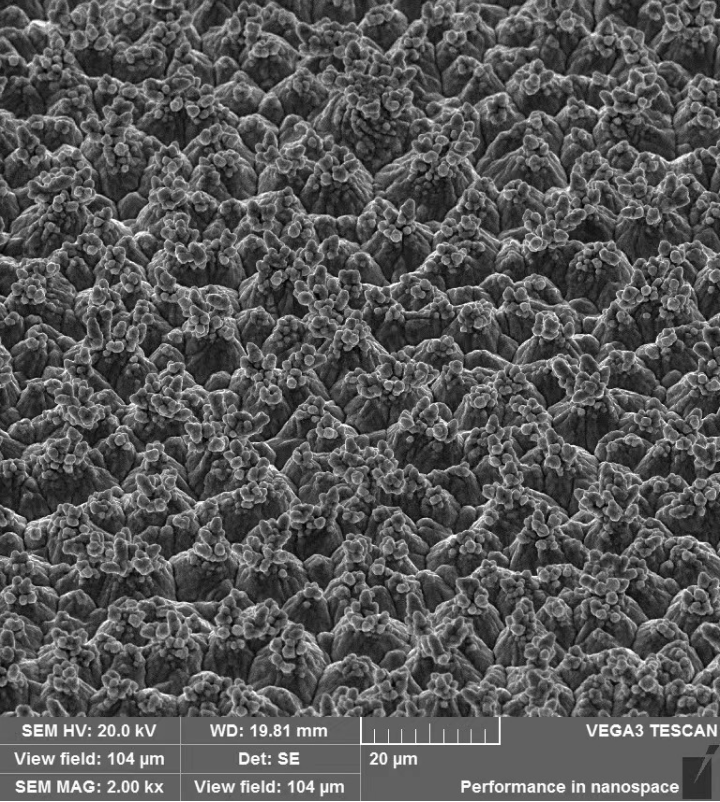

ACF atomized foil

ACF copper foil, as a high-performance current collector material, demonstrates unique value in the fields of supercapacitors and lithium batteries. In supercapacitors, its three-dimensional structure significantly increases the attachment area of electrode active materials, enhances the efficiency of charge storage, reduces internal resistance, and empowers high power density and rapid charging and discharging capabilities. In the field of lithium batteries, this copper foil reduces the shedding of active substances on the electrode sheets during charging and discharging through strong binding force, significantly extending the cycle life. Its resistance to electrolyte corrosion is suitable for advanced battery systems such as high-voltage and high-nickel ternary batteries. Meanwhile, its unique micro-nano roughening design, while ensuring mechanical strength, helps to enhance the commercialization of the next-generation high-energy-density lithium metal batteries, providing key support for the long-range driving of electric vehicles and the efficient operation of energy storage systems.

-

Downstream Applications

Lithium metal battery

Lithium-ion battery

High frequency high speed circuit board

Electromagnetic shielding -

Typical Characteristics

Enhance adhesion to electrodes

Improve electrolyte wettability

Enhance battery safety

Excellent anti-peeling strength -

product information

Representative characteristic data

-

-

SCF

-

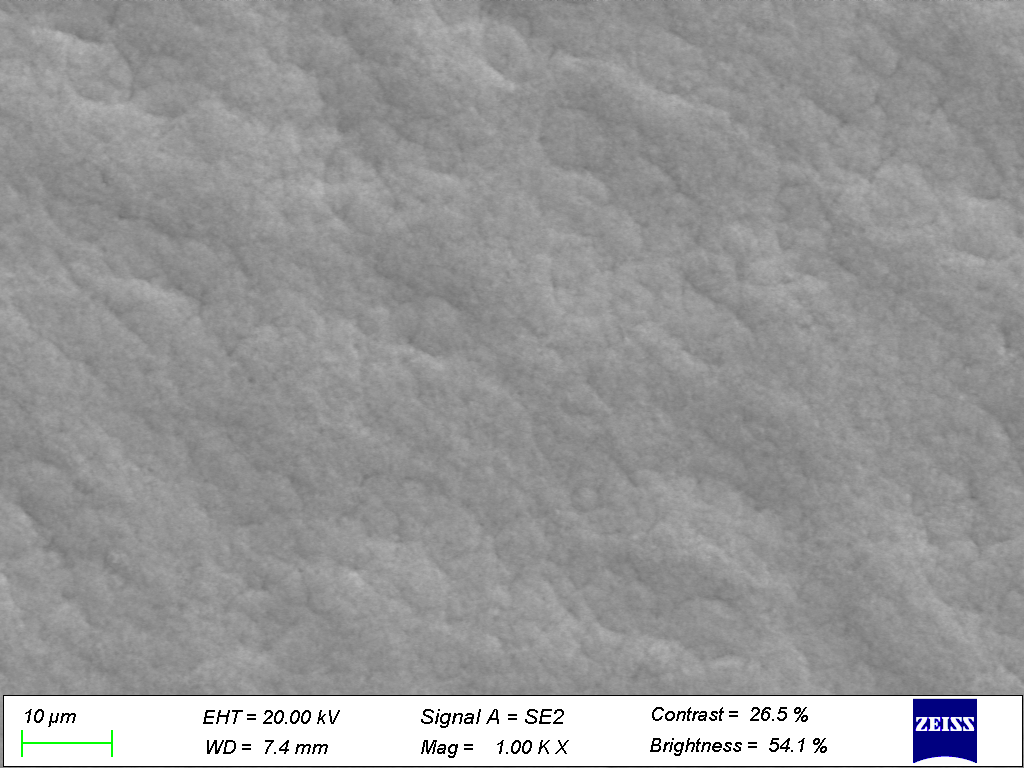

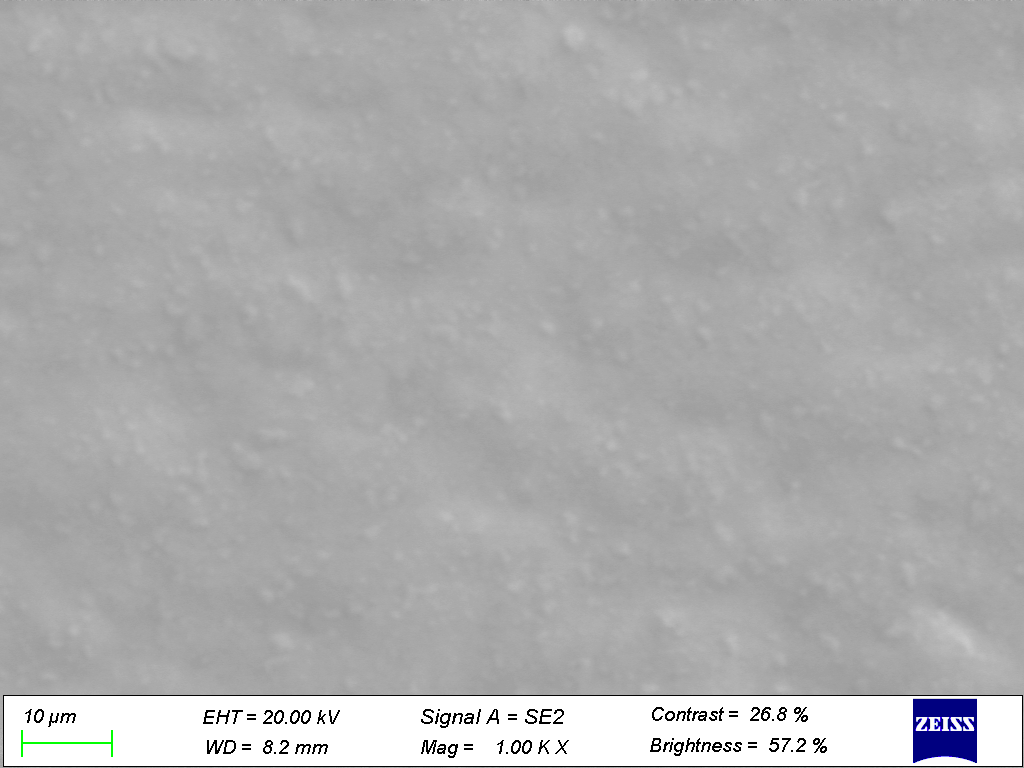

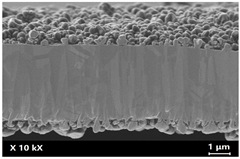

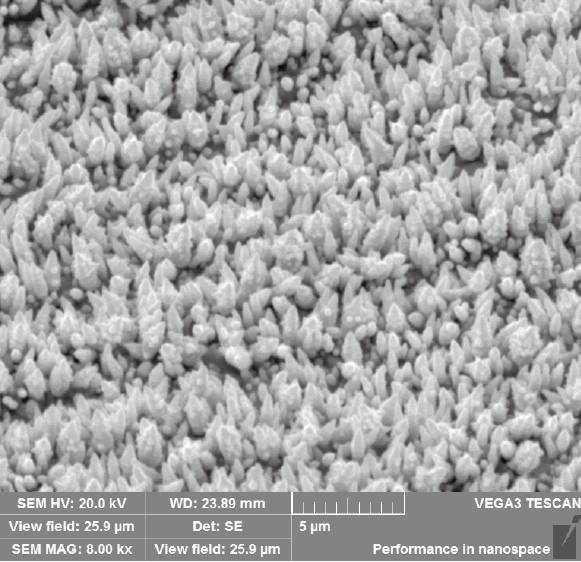

SCF foil

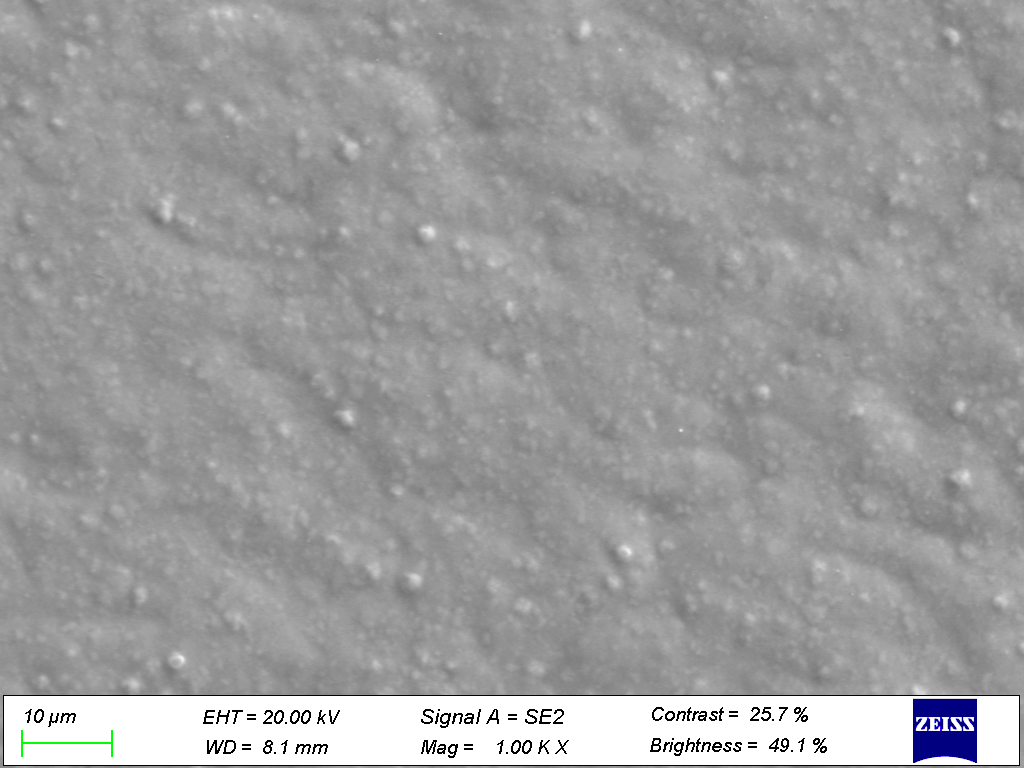

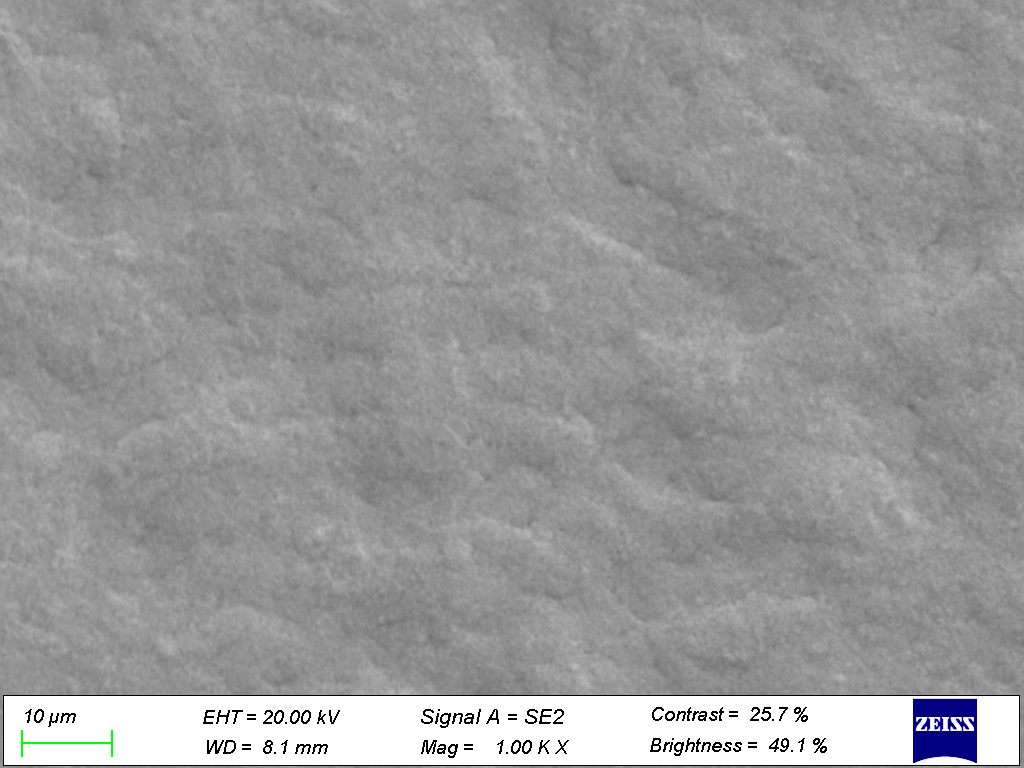

With its unique sandwich structure, SFC copper foil shows key application value in lithium-ion and solid-state batteries. In lithium-ion batteries, the double-sided coating not only provides an anti-oxidation barrier for the copper substrate, effectively inhibits the corrosion of the electrolyte on the copper foil, and ADAPTS to the high-voltage positive electrode system, but also its excellent electrical conductivity and high surface activity enhance the binding force with the active substance, reduce the internal resistance of the electrode, and help improve the energy density and fast charging performance. For solid state batteries, the inert interface characteristics of the coating can significantly reduce the side reaction with solid electrolyte, inhibit the risk of lithium dendrite penetration, and its high mechanical strength and thermal stability are more compatible with high temperature sintering process, providing a reliable guarantee for the interface stability and long-term cycle of sulfide/oxide system solid state batteries. By precisely controlling the thickness of the coating, SCF copper foil continues to unlock innovation potential in lightweight, safety and adaptation to a variety of battery technology routes, becoming the core material of choice for a new generation of high-energy battery design.

-

Downstream Applications

All-solid-state lithium-ion battery

Polymer lithium-ion battery

Flexible electronic device

Electromagnetic shielding -

Typical Characteristics

Enhance high temperature oxidation resistance

Improve acid and alkali corrosion resistance

Reduce interface contact resistance

Improve welding performance -

product information

Representative characteristic data

-

Copper foil for electronic circuits

-

V-SLP

-

R-SLP

-

C-IC1

-

C-IC1-C

-

V-SLP

V-SLP

-

Downstream Applications

BT/Class BT

IC packaging

Class Load Plate (SLP) -

Typical Characteristics

Ultra high tensile strength

Low roughness -

product information

Representative characteristic data

-

-

R-SLP

R-SLP

-

Downstream Applications

BT/ Class BT

IC packaging

Similar carrier Board (SLP) -

Typical Characteristics

High tensile strength

Low roughness -

product information

Representative characteristic data

-

-

C-IC1

C-IC1

-

Downstream Applications

BT/ Class BT

IC seal loading plate

High density interconnection board -

Typical Characteristics

Ultrathin

Low roughness

It can be separated after pressingU -

product information

Representative characteristic data

-

-

C-IC1-C

C-IC1-C

-

Downstream Applications

IC seal loading plate

coreless -

Typical Characteristics

ultrathin

Low roughness

The carrier layer is roughened

Adapt the coreless technique -

product information

Representative characteristic data

-

-

Copper foil for high frequency signals

-

Copper foil for high frequency signals

RHF1、VHF1、VHF2

-

Downstream Applications

PTFE

Hydrocarbon resin (PCH)

High-frequency circuit board -

Typical Characteristics

Low roughness

Stable peel strength -

product information

Representative characteristic data

-

-

HVLP High speed

-

RTF High speed

-

HVLP High speed

VHS1、VHS2、VHS3、VHS4

-

Downstream Applications

Low loss

Mid loss

High Speed Digital Circuit (HSD) -

Typical Characteristics

Low roughness

Good signal Integrity (SI) -

product information

Representative characteristic data

-

-

RTF High speed

RHS1、RHS2、RHS3、RHS4

-

Downstream Applications

Mid loss

FR-4

High Density Interconnect Board (HDI) -

Typical Characteristics

Low roughness

Stable peel strength -

product information

Representative characteristic data

-

-

V-SLP

-

R-SLP

-

H-SLP

-

V-SLP

V-SLP

-

Downstream Applications

BT/ Class BT

IC packaging

Similar carrier Board (SLP) -

Typical Characteristics

High tensile strength

Low roughness -

product information

Representative characteristic data

-

-

R-SLP

R-SLP

-

Downstream Applications

BT/ Class BT

IC packaging

Similar carrier Board (SLP) -

Typical Characteristics

High tensile strength

Low roughness -

product information

Representative characteristic data

-

-

H-SLP

H-SLP

-

Downstream Applications

BT/ Class BT

HDI

Class loading plate (SLP)/ sealing loading plate -

Typical Characteristics

Low roughness

Stable peel strength -

product information

Representative characteristic data

-

-

H-HCD

-

R-HCD

-

H-HCD

H-HCD

-

Downstream Applications

Automotive BMS circuit board

Medium to high TG epoxy

Cooling panel -

Typical Characteristics

Low roughness

Stable peel strength -

product information

Representative characteristic data

-

-

R-HCD

R-HCD

-

Downstream Applications

Automotive BMS circuit board

Medium to high TG epoxy

Cooling panel -

Typical Characteristics

Low roughness

Stable peel strength -

product information

Representative characteristic data

-

-

R-FPC

-

R-FPC

R-FPC

-

Downstream Applications

Flexible substrate (2L-FCCL)

PI/TPI -

Typical Characteristics

Low roughness

High bending resistance -

product information

Representative characteristic data

-

-

E-TFR

-

E-TFR

E-TFR

-

Downstream Applications

Consumer electronics

aerospace

Medical treatment -

Typical Characteristics

The thermal coefficient of resistivity is low

Excellent thermal stability -

product information

Representative characteristic data

-

-

H-HSP

-

HTE-R(thin)

-

HTE-R(thick)

-

H-HSP

H-HSP

-

Downstream Applications

PPO

Modified epoxy

Outer pressing -

Typical Characteristics

High coarsening amount

High peel strength -

product information

Representative characteristic data

-

-

HTE-R(thin)

HTE-R(thin)

-

Downstream Applications

FR-4

3C Consumer Electronics

Multi-layer board (MLB) -

Typical Characteristics

Moderate roughness

Stable peel strength -

product information

Representative characteristic data

-

-

HTE-R(thick)

HTE-R(thick)

-

Downstream Applications

FR-4

Power supply unit

Automobile sheet -

Typical Characteristics

Moderate roughness

Stable peel strength -

product information

Representative characteristic data

-